User reports

EEP-Robotics GmbH is proud to develop customized solutions and systems that are successfully used by our customers worldwide.

REFERENCES / USER REPORTS

Successful solutions in use

Our technologies and services are designed to meet specific requirements in a wide range of industries and achieve sustainable success.

On this page you will find a selection of references and user reports that show how our innovative solutions are implemented in practice.

Each report gives you an insight into the challenges we have overcome together with our customers and how our systems and solutions have made a significant contribution to increasing efficiency, productivity and sustainability.

From the automation of complex production processes to the implementation of smart robotic systems – our customers benefit from our expertise and our commitment to the highest quality.

Be inspired and learn how EEP-Robotics has helped to transform our customers’ business processes and sustainably strengthen their competitiveness.

We pride ourselves on building long-term partnerships and shaping the future of the industry together with our customers.

Projects

Egger system “Mixing on pallet” AB1808062

This system mixes a wide variety of beverage products on pallets using a Kawasaki CP300L robot.

Read more

Projects

Employee-friendly optimization

The WÜRTH headquarters in Germany, Bad Mergentheim, has commissioned the company Knapp and EEP to create a pilot project to automate their work processes robotically.

Read more

Projects

Photovoltaic production

Solar energy has a great future. EEP is contributing to this by implementing state-of-the-art technologies in this highly regarded production process.

Read more

Projects

Food

Palletizing requires customer-specific solutions. The realization of a system that efficiently groups filled baking products is shown here.

Read more

Projects

Color filling

Precise dosing of printing inks into different containers is achieved in this system by means of linear robots and the integration of a gripper changeover station.

Read more

Projects

Building materials industry

This system was designed to fill, close and palletize plastic containers for the construction sector in precise doses.

Read more

Projects

Laser welding

This technical report shows the three-dimensional welding of stainless steel components with precise joining seams and the associated sophisticated clamping technology as well as the integration of robots and industrial lasers.

Read more

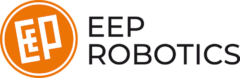

Projects

Pipe production

Automated handling of welded tubes in a special production plant for the automotive industry.

Read more

Projects

Solar collectors

A state-of-the-art, comprehensive production facility for the manufacture of hot water collectors reflects the upswing in alternative energy.

Read more

Projects

Palletizing

Automated palletizing maximizes productivity in practically every industry. This project report shows the efficient stacking of cartons using linear robots in a system for two production lines.

Read more

Projects

Snow chain production

Description of a system with a 6-axis articulated arm robot for handling and manufacturing snow chains, including loading.

Read more

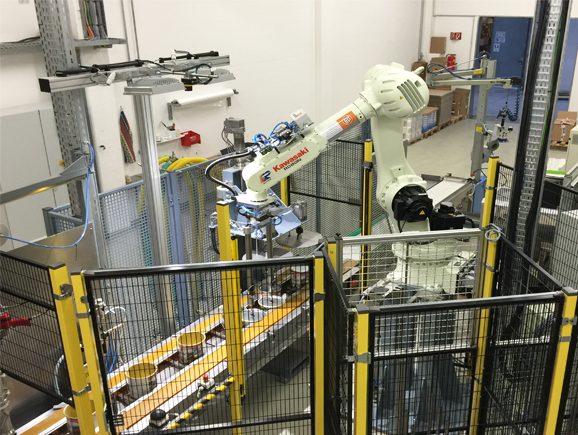

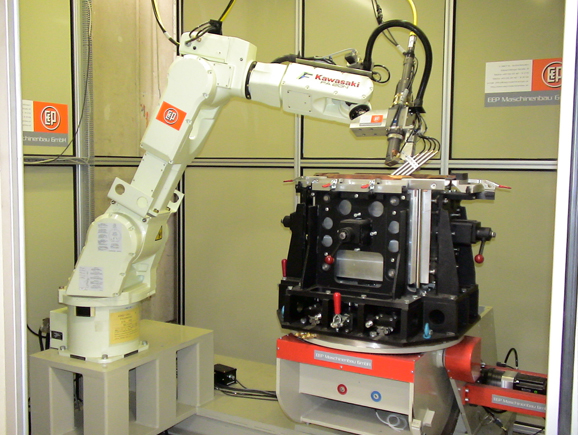

Projects

Aluminum die-cast parts

The handling and processing of die-cast aluminum parts for the automotive industry is presented here.

Read more

Projects

Dispatch palletizing in intralogistics

Implementation of automated technologies in the field of robotics. Robot KLT picking (KLT = small load carrier) with integrated camera recognition is used in the areas of picking and dispatch palletizing.

Read more

Projects

Solar system installation

This report shows the implementation of a precise integrated assembly solution for photovoltaic modules using Kawasaki 6-axle vehicles.

Read more

Projects

Automation in use

Report on the replacement of an existing system with a state-of-the-art palletizing robot as part of the modernization of the family-owned company HL Hutterer & Lechner GmbH.

Read more